Building Science 101: Roofs: Venting and more

Once the soffit vents on this Cape Elizabeth addition, designed by the author and built by carpenters Ethan Lavendier and Rangeley Morton of O’Brien Wood & Iron, have been installed, they will work with the gable-end vent to keep moisture from accumulating and help prevent microbial growth. Courtesy photo.

By Michael Maines

WITHOUT A ROOF that keeps sun, rain and wind out, the rest of your home won’t last long. We all know what roofs are and what they do, but you may not know some of the important things to consider when it comes to building or replacing a roof—specifically, whether or not to vent it, and how.

“Venting” is one of those construction terms with many meanings. When it comes to roofs, it means allowing the air under the roof cladding to escape to the outdoors. Venting is usually passive, via grilles along the eaves and ridge (that is, the lowest and uppermost portions of the roof), in the gable ends or, sometimes, inserted directly into the roof surface. Occasionally roofs are vented mechanically, with fans built into the roof itself or installed in cupolas or gable ends.

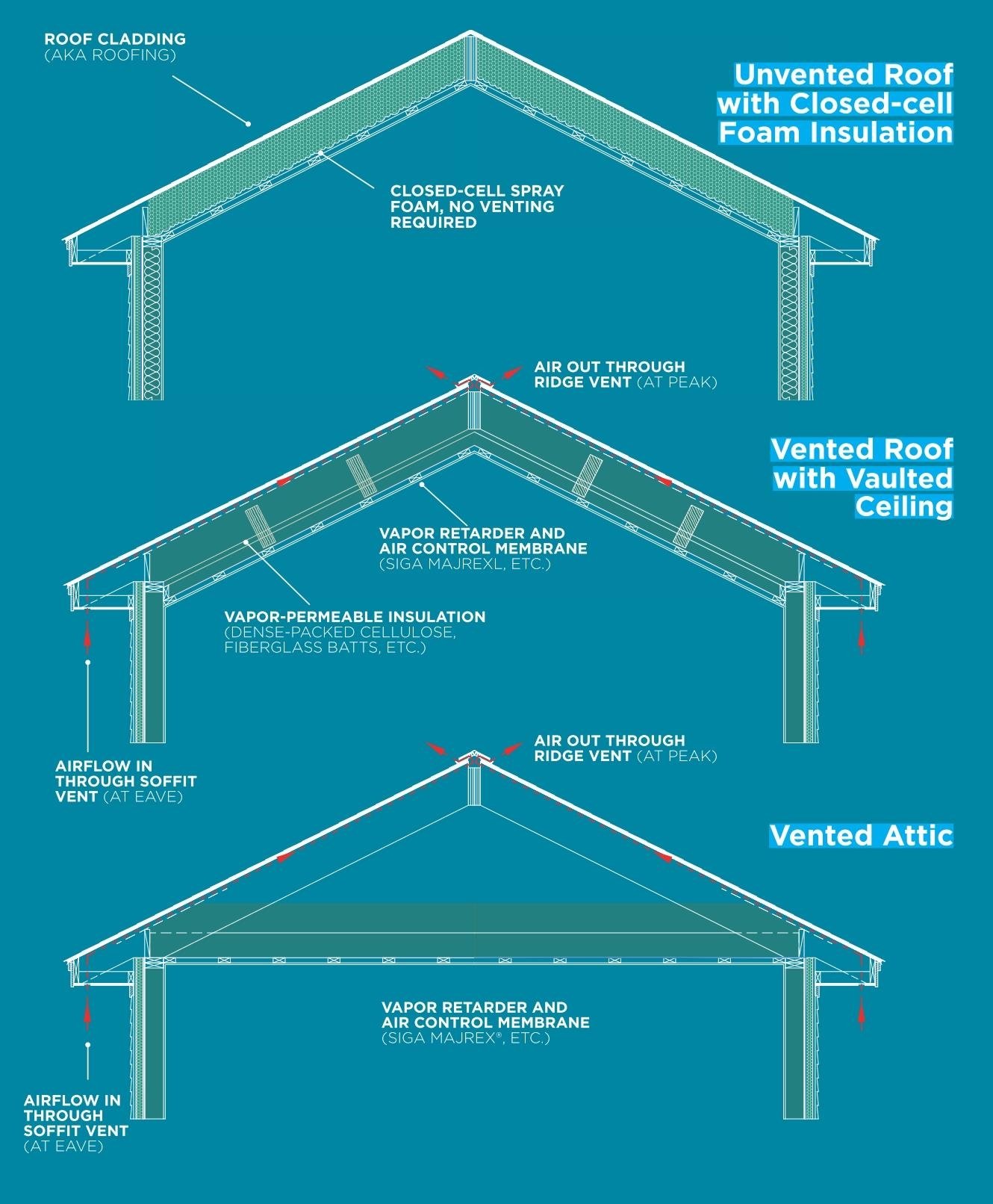

The main reason for roof venting is to evacuate moisture making its way from the interior to the exterior, and, secondarily, to reduce the risk of ice dams. Venting also reduces the temperature of the roof surface or attic space a little, but not enough for it to be a primary factor in deciding whether to vent a roof. Roofs are vulnerable to moisture accumulation because warm air tends to rise, and it usually carries more moisture than outdoor air. Once it reaches the highest point, that warm, moisture-laden air desperately wants to get to the relatively cool, dry outdoors; that “desire” is called vapor drive. On cool, clear nights, roofs lose heat directly to space, cooling the roof surface temperature below the ambient outdoor air temperature, resulting in stronger vapor drive and higher risk of moisture accumulation.

The problem with outward vapor drive is that while most construction materials are slightly permeable to moisture, almost none of the roof cladding materials we use are permeable. Moisture traveling from inside the building toward the exterior gets trapped as condensation in the layer below the cladding, the roof sheathing. Damp sheathing leads to microbial growth and eventually rot. (Building science nerds will correct me—the moisture mostly accumulates via adsorption and absorption, so like building scientist Bill Rose, I usually use the term “moisture accumulation” instead of condensation.)

There are a few ways to address this potential issue, but they all come down to keeping water vapor from reaching a surface where it can accumulate.

The first and most common solution is to vent the roof—whisking away the damp air before it can accumulate. The less damp air that needs to be whisked away, the better, so it’s important to have an air barrier and vapor retarder on the interior side of roof assemblies. Painted drywall (without penetrations from lights or other devices) can serve this purpose, or the polyethylene sheeting that used to be common. And now that vapor-variable membranes such as SIGA’s Majrex® are available, they are often a good choice. But some water vapor will still get through and needs a path to the outdoors.

House with both a gable-end vent and soffit venting.

Older homes often have attics with grilles in the gable ends, providing a bit of airflow. While they usually don’t provide enough airflow by current building code standards, some venting is better than none, and it’s often enough. Testament to the fact that a house operates as a system, the main indicator of moisture in roofs is a damp basement or crawl space (moist air in the basement will make its way to the roof), so fix that before worrying excessively about your existing roof.

For new homes and renovations, you don’t need to guess at how much vent area you need. MUBEC, Maine’s building code specifies the required vent area as 1/150 of the area being vented. In a 24-foot by 36-foot house with a 1,008-square-foot attic, 1/150 of that is 6.72 square feet, so that’s the total vent area you would need. That could be provided with two 3.36-square-foot grilles installed in gable ends. Allowing extra space for louvers that block wind-blown rain, in this example the grilles would need to be about 2 feet by 2 feet.

Gable-end vents aren’t always used, for various reasons. Not all roofs have gables, for example, or these vents can allow wind-blown rain and snow to enter, or they may not be as pest-resistant as other options. And they don’t work at all with vaulted ceilings that lack an attic space. Most new homes and renovations use a combination of soffit vents and ridge vents. The total vent area still needs to be at least 1/150 of the area being vented (i.e., the floor area), with a caveat: if at least 40% and no more than 50% of the total vent area is within 3 feet of the ridge, the ratio can be reduced to 1/300 of the floor area—half as much as we need when the vent area is not evenly divided between high and low areas of the roof. Typical punched-aluminum soffit vents and plastic-matrix ridge vents happen to fall within this range on simple roofs for average-sized homes, but to be safe, you, your designer or builder should do the math on how much net free-vent area is required vs. what is provided by standard products.

Another advantage of using a venting system that includes soffit vents is that it can help protect against ice dams. The cool air flooding the underside of the sheathing keeps the roof surface cold, so heat escaping from the interior is less likely to melt snow on the roof, the main cause of ice dams.

There is a heat-reducing aspect to venting; research by Building Science Corporation shows a slight reduction in surface temperatures with a vented roof, which could extend the roof cladding’s life by an estimated 5–10% compared to installation over an unvented roof. In the past, most roofing manufacturers would not provide a warranty for their products on unvented roofs; now, the reverse is true. Warranties are pro-rated, so a 5–10% difference in life span is not worth a lot.

There are a few methods for creating an unvented roof, but all the safe ones have a way to keep warm, moist indoor air from reaching a surface cool enough to condense on. One way you should not do it is to install fluffy (air-permeable) insulation in a typical rafter bay without a vent space or additional insulation layers. Some professionals recommend using variable-permeance membranes and fluffy insulation without venting or additional insulation layers, and there are installations that have not failed, but there are many things that can go wrong, and the science says it’s a risky assembly.

One way to make an unvented roof safe (and code-compliant) is with continuous exterior insulation, usually rigid foam. Installed above the roof sheathing, rigid foam (or other rigid insulation) keeps the sheathing and framing relatively warm and dry, enough so that fluffy insulation can be safely installed in the rafter cavities. In Climate Zone 6, which includes most of Maine, we need 50% or higher of the roof ’s total R-value to be in the exterior layer. Using more than 50% of the total R-value on the exterior insulation makes for a safer assembly. Maine’s current building code requires R-49 in roofs (R-60 in Portland), so at least R-25 should be in the exterior insulation layer and at least R-24 in the framing cavities (R-30 for both layers in Portland).

But while a roof insulated on the outside is great from a building science viewpoint, it’s more complicated to build than most roofs and not very common. Another way to create an unvented roof is simply by using spray foam, but there are caveats. Closed-cell foam is often thought of as blocking all moisture movement, but it’s actually not completely vapor-closed: it does allow moisture to pass—very slowly—but it slows vapor movement enough to make it safe for use in unvented roofs. If rafters are wet, icy or dirty the foam may pull away, and these gaps are not good, as they allow moist indoor air to reach the cold sheathing. Foam installers often claim that less than the code-required R-49 is adequate, due to foam’s air-sealing abilities, but that is neither correct nor code-compliant. Any insulation can be installed in an airtight manner. One more warning: open-cell foam is code-compliant in unvented roofs because it is airtight, but because it allows water vapor to pass through, it is not safe (or code-compliant) to use in cold-climate roofs, unless a vapor-retarding material is used on the interior side.

Building professionals concerned about the environment and occupant health usually try to reduce how much foam is needed, so we tend to gravitate to vented roofs that work well with insulation materials that have smaller carbon footprints. But venting some roofs is challenging, such as those in old homes, homes with dormers or hips, or low-slope roofs. For these types of roofs, spray foam insulation is often the only good way to insulate. If you want to reduce the environmental impact and potential health risks, and possibly save some money, too, you can consider a flash-and-batt or flash-and-fill approach. That’s a mix of closed-cell spray foam toward the exterior, with fluffy insulation (cellulose, fiberglass, mineral wool, sheep’s wool, etc.) toward the interior. The same ratio rules apply as for exterior insulation: at least 50% of the total R-value must be in the spray foam layer. Because this is a long-term water accumulation issue and not an energy-use or code-compliance issue, it’s important to use the aged R-value of the foam. When new, the R-value of foam is roughly R-7 per inch, but over time, air displaces the chemical gases in the foam until it eventually performs at about R-5.6 per inch. So to get a code-compliant, flash-and-batt unvented roof, you would need at least R-25 in the foam layer, or 4 ½ inches, and R-24 in the fluffy layer—about 6 ½ inches of dense-packed cellulose or 6 inches of mineral wool.

This article appeared in the Spring 2022 edition of Green & Healthy Maine HOMES. Subscribe today!

Find Maine experts that specialize in healthy, efficient homes in the Sustainable Homes Business Directory.