Sourcing local wood building materials: Decking

Northern white cedar is an excellent choice for decking, or a boardwalk, as shown in this house in Harpswell, designed by Penniman Architects. Photo by NCOB photo.

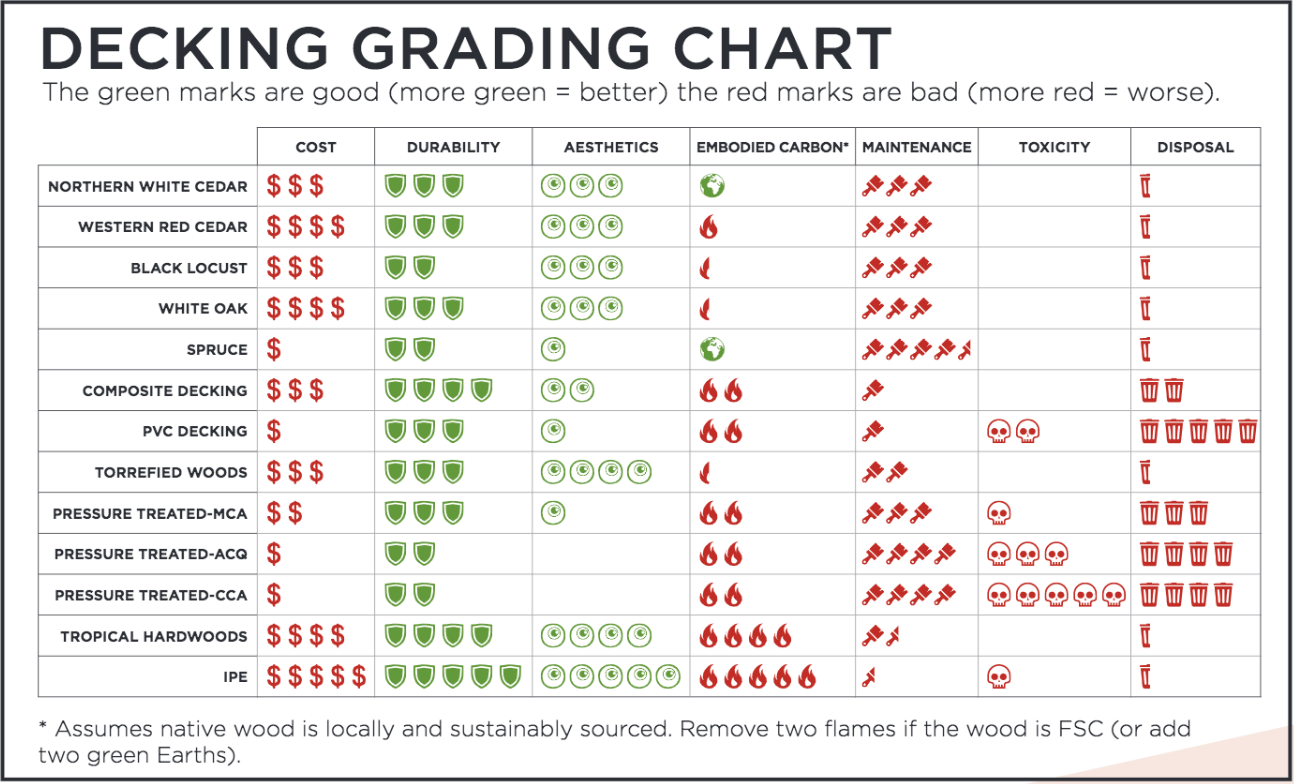

Decks are people places. They are where we barbecue, catch some rays, tend our container gardens. Hardscape patios are ideal for durability and are usually very attractive, but because of budgets or site considerations (think sloping sites), decks are ubiquitous for outdoor relaxation. Pressure-treated wood is the material of choice for framing the structure, but there are endless choices to consider for finishing off the decking and features of these outdoor spaces.

NORTHERN WHITE CEDAR

One of the best decking materials is closest at hand. Northern white cedar (also called eastern white cedar) is aromatic and its grain character speaks of Maine. Most importantly, it’s filled with resins that make it naturally rot-resistant without any preservatives. You can stain it if you want to commit to maintaining that color, or you can just let it weather to grey. Some people gently power wash their cedar decks every spring to clean and remove mold or other natural debris that can lead to rot. Northern white cedar doesn’t come in large sizes, but it does have a high percentage of heartwood, the most rot-resistant part of a tree. It will outlast its more well-known western cedar cousins.

One downside of cedar is that it isn’t dense, so it is more susceptible to scratching from rambunctious kids and pets. It’s also prone to splitting if it’s not well installed. In direct southerly sun, it can take a beating and get fibrous. However, under a farmer’s porch on the eastern side of my house, I have a cedar deck that is almost 20 years old and requires almost no maintenance. White cedar decks are very attractive, like natural New England cedar shingles. Northern white cedar ranks mid-range in affordability, and high for ease of installation.

COMPOSITE DECKING AND PVC

These materials are growing in popularity because they come in endless colors and are virtually maintenance-free (there’s no such thing as “no maintenance”). The drawbacks are they rank low for looks and sustainability, and high for cost. Decking still connotes wood, so most manufacturers try to mimic grain patterns, but they look fake. The composition and manufacturing of these deck materials are the major disadvantages. Composites contain a mix of wood residues and recycled plastics. Recycled plastic is better than virgin plastic, but it’s still a fossil fuel derivative. PVC (polyvinyl chloride) produces all kinds of nasty emissions in its manufacture and if it ever burns, the resulting smoke is incredibly toxic. Composite/PVC decking ranks low in affordability and mid to low for ease of installation, depending on the material.

PRESSURE TREATED

Pressure treated wood is everywhere and it’s a very affordable option. It’s typically made from southern yellow pine, a species of the southeast U.S., where it is grown in even-row, monoculture plantations. The wood is less environmentally troublesome than when the industry was using chromated copper arsenate (CCA), although the copper-based pesticides used today still pose risk. Goggles, gloves and dust masks are highly recommended while fabricating PT. It’s a bit harder than cedar and spruce, so it’s more resistant to wear. Best practice is to seal every cut for better protection, and it’s pretty easy to split during installation. I don’t think it has any redeeming qualities aesthetically unless you use a solid stain, although over time it does grey out. PT ranks high in affordability and high for ease of installation.

WESTERN RED CEDAR

Outside of New England, western red cedar is most people’s idea of cedar. Fragrant and reddish-brown in color, western red cedar grows big and therefore produces longer, straighter wood than its eastern cousin. It’s very rot-resistant but not as resistant to insect damage as northern white cedar. We used to install much more WRC before costs increased significantly. Costs and installation are similar to northern white cedar.

IPE & OTHER TROPICAL HARDWOODS

Beautiful and rot immune, tropical hardwoods are a source of consternation in the sustainable building community. Ipe is especially popular in high-end construction but has been implicated in illegal logging and rain forest deforestation. Because it grows outside of our country, transportation is another huge drawback. Clients and designers like ipe because it is very durable and beautiful, especially if you keep it stained and oiled. Its density slows installation because specialty fasteners are needed, and/or every screw needs to be pre-drilled. Cost and sustainability often push ipe out of consideration for the typical decking project.

BLACK LOCUST

Black locust is a wonderfully durable wood, historically used in fence posts. It’s native to the Appalachia highlands, where it grows so fast it’s almost considered a weed. A quick Google search turned up several North Carolina sources, one of which is FSC. There are New England suppliers, but availability is limited, so expect to place a custom order. Like ipe, black locust is very hard, so installation can be more challenging, although it can come pre-grooved for hidden fasteners.

TORREFIED WOOD

Torrefication is a relatively new process that turns rotprone wood, such as poplar, into very durable wood. In the process, wood is heated to very high temperatures, under pressure and without oxygen, to drive out moisture and superfluous volatiles. The resulting wood has a nice amber color and is very resistant to deterioration and fungal attack. The Roux Center for the Environment at Bowdoin College is clad in cambia, a torrefied wood from Northland Forest Products in Kingston, N.H. that is weathering much like cedar.

SPRUCE

For tight-budget projects, spruce is a great solution for certain installations. With very little rot resistance, stain and constant maintenance will be required, as will repair or replacement unless the decking is protected from strong direct sunlight and the majority of rainfall (i.e. under a porch or overhang). For the DIY homeowner, spruce offers a very affordable and natural material that can be attractive with the right stain and maintenance. It’s native to New England, so sustainability points are high if it can be maintained well enough to avoid major deterioration for an extended time.

WHITE OAK

Another native material that flies under the radar, white oak has fans throughout New England as a beautiful, rot-resistant decking material that can hold up well to wear and tear as well as rotting. Unfortunately, it isn’t widely available as decking due to higher costs and easy alternatives. White oak is similar in some ways to the southern yellow pine used with PT but is much more attractive and durable.

NORTHWESTERN CEDAR

Alaskan yellow cedar and Port Orford cedar are two Northwestern species that are similar to northern white in most aspects. Port Orford is very beautiful and quite durable but is currently hard to source. Many lumberyards stock Alaskan yellow cedar as a good decking solution; unfortunately, the transportation issues for New England projects draw down the sustainability rating for this material. These two cedars are just a little harder than other cedars.

Ben Hemberger leads Benjamin & Co., a small group of passionate builders in Brunswick that specializes in timber frames and high-performance homes. When he’s not hard at work, he’s outside enjoying Maine’s four seasons with his wife and three kids.

This article appeared in the Fall 2020/Winter 2021 edition of Green & Healthy Maine HOMES. Subscribe today!