Choosing Insulation

A green architect’s guide to selecting the right insulation for the right job

By Chris Briley

Whether you are a homeowner, a builder or designer, you might find yourself needing to decide what insulation to use on your project, or you might be wondering if there’s a better choice than your default product. The different choices and applications can be intimidating and sometimes confusing.

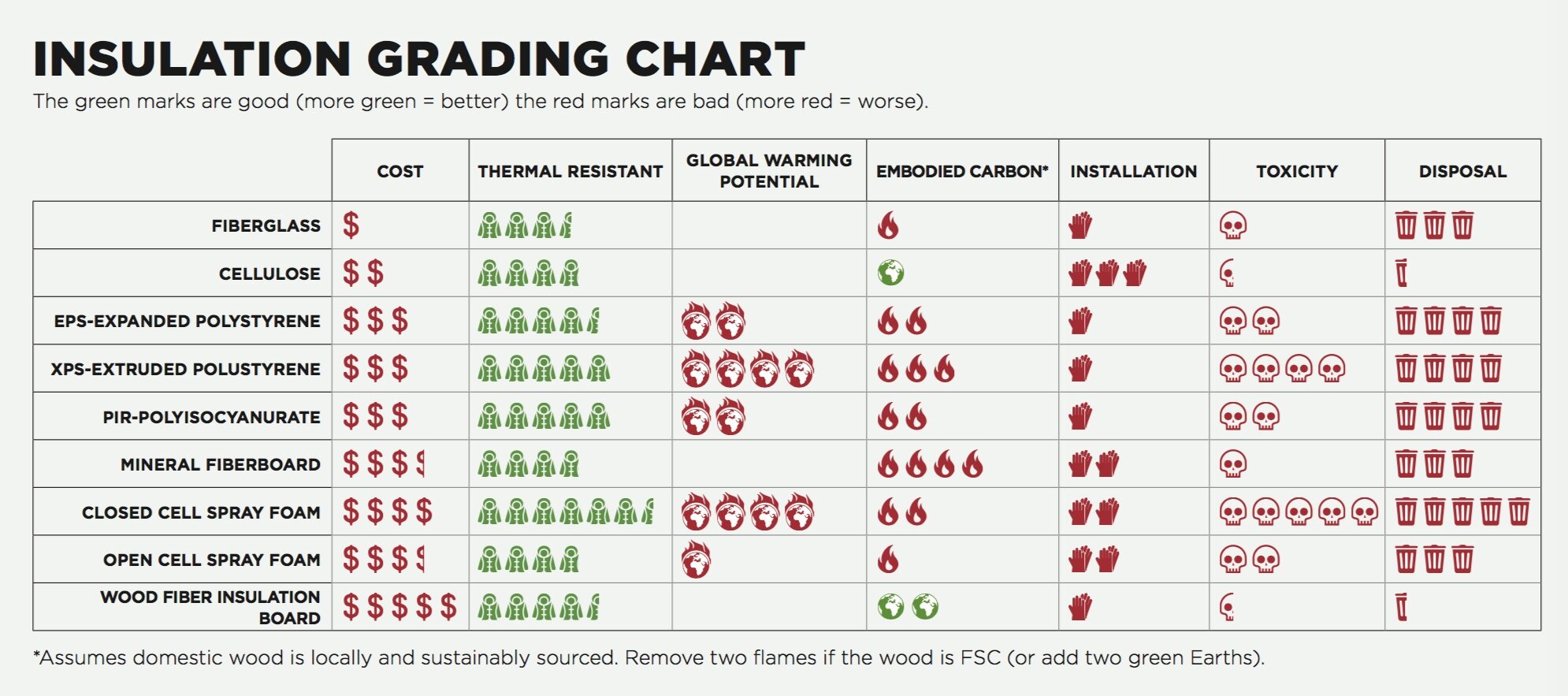

THE BASICS: Heat always travels from hot to cold (high energy to low energy), and it does so in three basic ways: conduction, convection and radiation. Conduction is heat energy traveling directly through a material, like a ceramic mug full of piping hot coffee. The heat of the coffee travels through the ceramic to the cool air, so much that you might need a handle on the mug to be able to hold it. For most of this article, we’ll be talking about this method of transfer. The building envelope is the mug, the hot coffee is the warmth of your house and the cold air is, well, the cold air. Insulation’s job is to slow that transfer by means of resistance. This resistance is measured by a material’s R value (see sidebar on R value). In other words, we’ll be trying to turn that ceramic mug into a Thermos® by changing the material from which the mug is made. Along with the resistance of the insulation, we’ll be considering many other attributes such as the material from which it is made, its toxicity (or its effect on the indoor air quality), its global warming potential, how it is installed, its best application and its effect on moisture migration through the building envelope. There’s so much to cover, but don’t worry — we’ll have a handy little chart at the end of the article to help summarize it all.

Fiberglass R-3.5/inch ±

FIBERGLASS BATT INSULATION is probably what most people think of when they think of insulation — the fluffy pink felted stuff that comes in rolls or bags at their favorite big box store. It is made from molten spun glass in a manner not dissimilar to cotton candy (maybe the inspiration for choosing a pink color?). It gets its insulative properties by creating so much surface area (around all the little fibers) that the air is trapped in all the minuscule nooks and crannies; it is this trapped (dead) air that is actually doing the insulating. Being made of glass, it is fire-resistant, rot-resistant and can be made from recycled material.

This spun glass doesn’t stay together in a felted blanket by magic. It takes glue binders, which can be made from any number of chemicals and additives. This is where the green-minded person begins to really focus their discrimination. If one buys the cheap stuff off the shelf today, there’s a high likelihood that it has no recycled content, contains urea-formaldehyde in the glue binder (a known carcinogen) and is loaded with other dyes and chemicals of uncertain origin (that pink color doesn’t happen naturally).

Thankfully there’s been great progress over the past decade in making greener FG products more available. Companies like Knauff and Johns Manville have been making such products for years, and now even Owens Corning and Certainteed are joining them.

Application

Fiberglass typically is a fluffy product suitable for interior cavities such as walls, roofs and floors. It’s not often used below grade (underground) or outside, though some FG products are sold as “rigid board insulation” meant for exterior environments.

Fiberglass companies have begun to challenge the loose- ll cellulose market by making a blown-in product. This is often used in attics where a couple of fluffy feet of insulation can be piled up easily, like little cottony tufts shot out of a blower.

Remember these are glass fibers (sometimes coated with carcinogens) that you are blowing in and stuffing into cavities. Protective eyewear, gloves and especially masks are vitally important!

Cellulose R-3.8/inch

Photo courtesy of Emerald Builders

I’M GOING TO GO OUT ON A LIMB and say this is the most sustainable form of commercially available insulation on the market today. Our office has been using and specifying it as our go-to insulation for years.

Cellulose is made from recycled paper and wood pulp, shredded and fluffed and treated (typically) with a borate salt to make it pest-resistant, mold-resistant and fire-resistant (resistant being a relative term for a product made primarily of paper). Being made of an organic material, it is best suited to interior applications and should stay out of areas of higher relative humidity (such as crawl spaces and unconditioned basements).

It has a similar R-value to fiberglass and, like fiberglass, it is great for cavity insulation in walls, roofs and floors. Its material cost is quite low but, in almost every case, has a labor cost that makes it slightly more expensive. Its advantages, however, are usually well worth the premium cost.

Application

Remember at the beginning of this article I mentioned convection as a means of heat transfer? If your building envelope has some leaks and cracks (which it will, but hopefully these have been greatly minimized) heat will be hitching a ride on the air that flows through those cracks. Fiberglass does very little to deaden or stop any airflow (you can literally blow out a candle through it).

Cellulose is typically installed at a high density of 3.5 pounds per cubic foot in a process called dense packing. At this density, it does a fabulous job of deadening the air within the building cavities. To be clear, this is NOT air sealing and should not be counted on to do that work for your wall assembly, but it certainly helps and adds a little forgiveness for the minor flaws in building assemblies.

Dense packed cellulose is usually installed by first stapling a polyester mesh tight across the interior framing of your home, and then the installer will cut a small opening for the hose end of the blower and pack each cavity full of insulation. Sometimes a much less vapor-permeable material is used to retain the insulation, but this would be a special situation where it is being used as a vapor control layer (moisture migration through wall assemblies would be another article altogether). This higher density is also great for sound attenuation.

Another form of installation is a wet-applied method, wherein water is added to the insulation shot onto the wall, where it sticks and builds up to the desired thickness. After it dries, the excess is shaved off at the face of the framing. This method requires more finesse and equipment, as well as time and conditions for proper drying, but it saves the labor of stapling up an insulation retention layer. Both methods of installation are a dusty mess. Masks are a must, and goggles and a respirator are a very good idea.

Loose- ll cellulose has been around for ages and still is an incredibly cost-effective way to add insulation to an attic floor. Like the loose- ll fiberglass (in fact the cellulose version is its inspiration), cellulose is simply shot out of a large blower hose and piled to the desired depth.

GLOBAL WARMING POTENTIAL

Cellulose as a product is very low in embodied energy and carbon. In fact, because it is a plant-based material, it can even be carbon negative, meaning it is made from a material that has absorbed more carbon (as a tree building itself from the carbon dioxide from the air) than it expelled in its production. Add the fact that it usually has a high percentage of post-consumer recycled content and no toxins, and you have a real winner on your hands.

Rigid Polystyrene

Photo courtesy of Briburn

UNFORTUNATELY, THERE ARE PLACES where cellulose can’t go — places that will be buried, are exposed to excess moisture or that need to bear the weight of building components. For these locations, rigid polystyrene products dominate the market for their relative affordability and durability. Polystyrene is a long-chain hydrocarbon that, when expanded or extruded to a light density, creates a highly insulative material.

EXPANDED POLYSTYRENE – EPS R-4.5/INCH

We’re all familiar with EPS: it’s the white, lightweight packaging material that looks like it’s formed from little beads (because it is). Polystyrene beads are usually placed in a mold and, under heat and an injection of pentane, they expand to ll the shape of the mold.

EPS can be formed in sheets and used as building insulation in many forms and densities. It is inorganic, naturally water-resistant and will not rot. Because it is flammable, it is often relegated to below-grade applications such as sub-slab insulation and insulated concrete forms. It is also often the insulation used in structural insulated panels or in other assemblies where it is properly covered by other less-flammable materials. When graphite powder is added during its expansion process, EPS’s conductivity is reduced (and R-value increased) by as much as 23%.

EPS is made of tiny, airtight, closed cell beads, but the beads themselves do not form perfect seals with each other throughout the whole material. As such, the product is somewhat vapor permeable and only qualifies as a class II vapor barrier. This has its advantages and disadvantages depending on the intended use and location of the product within any building assembly.

EXTRUDED POLYSTYRENE – XPS R-5/INCH

Similar to EPS, XPS is made from a raw polystyrene product but is expanded differently in an extrusion method, yielding a better insulation value and a denser product. You often see this on job sites as “blue board” or “pink board.” It is also naturally inorganic and flammable, but since it is often used above ground as well as below, it almost always contains flame retardants, one of its significant drawbacks.

Toxicity

In 2009, BuildingGreen rocked the insulation world by publishing an article on the hazards of the fire retardants used in EPS and XPS called HBCD (hexabromocyclododecane). In short, HBCD is a nasty bioaccumulative toxic chemical that has, thankfully, been phased out of both products. A new flame retardant, BFR or brominated flame retardant, replaces it. Dow Chemical touts this as a green alternative, but the health impacts of this persistent chemical compound are still not fully known; it is already coming under fire in Europe.

For this reason, it’s good to know if your EPS or XPS has a flame retardant in it when ordering/specifying it. (If it is XPS, spoiler alert: it probably does). And you certainly don’t want it in your interior environment, if in your project at all.

GLOBAL WARMING POTENTIAL

Unlike EPS, which typically uses pentane as the blowing agent to expand the polystyrene, XPS traditionally uses hydrofluorocarbons (HFC 134a to be specific). This gas is over 1000 times more damaging than CO2 as a greenhouse gas in our atmosphere. Pentane is seven times more damaging. Even though it is fairly contained at the manufacturing plant, these gasses are trapped in the product and leach out over time, also degrading the R-value from 5.5 down to 5. As a result, the environmental payback of XPS as a product could be well over a decade and possibly in nite; if you are able to achieve the same R-value with another product, it’s worth considering.

This said, keep an eye out for new products that have different blowing agents with lower GWP. As of the writing of this article, Dow and Owens Corning are working on solutions.

Polyisocyanurate – PIR R-6.5/inch

Photo courtesy of Emerald Builders

ALSO A THERMOPLASTIC BOARD, the chemical makeup of Polyisocyanurate (PIR) is akin to polyurethane. Much like Polystyrene, it can be used in exterior moist environments but, because of its ability to absorb water, it shouldn’t be used below grade. PIR’s popularity emerged in the roofing industry, which needed a rigid board that could take the high temperatures of a “hot-tar” or modi ed bitumen roofing application. As this implies, its ignition temperature and melting temperature are much higher than EPS or XPS. Like EPS, PIR uses pentane as its expansion gas but, unlike XPS, it usually doesn’t require an added re retardant.

PIR also boasts one of the highest R-values per inch of any rigid insulation, although this comes with a considerable caveat: performance decreases as the temperature drops (when you’d need it most!). This is a recent revelation in the building industry and the opposite of what one would expect. All other insulations mentioned in this article perform marginally better as the temperature decreases and the difference in temperature from the cold outside to the warm inside increases. The full extent of this phenomenon has not been fully explored, but enough evidence suggests that here in Maine, where our winters can be deeply cold, XPS may outperform PIR on an annual basis.

PIR is usually coated with foil or a fiberglass face: PIR is basically Polyurethane mixed with MDI (Methylene diphenyl diisocyanate), both of which are essentially adhesives, meaning PIR is itself an adhesive. The fiberglass coating has its advantages in the roofing industry, offering an effective substrate for roof membranes and mechanical fasteners, but it also is great for milder climates because the foil face makes an excellent radiant barrier. The foil has an added bene t of being a vapor barrier and an air barrier (if taped and sealed well). This can be great or terrible depending on how thoughtfully it is located in the building assembly.

Mineral Fiber Insulation R-3.8/inch ±

MINERAL FIBER BATT is similar to fiberglass in wool is also unaffected by water and resistant to the absorption its manufacture, but the ingredients are different. Instead of glass, it uses basalt (an abundant volcanic rock) and steel slag (a by-product of the steel industry.) These materials require much higher temperatures to form, making mineral wool one of the highest in embodied energy and embodied carbon.

Like fiberglass, its fibers are held together with a binder that has historically been phenol and urea formaldehyde-based. Only recently has the industry begun to offer a mineral wool product with bio-based binders, but these are still hard to come by. For these reasons, our office relegates this product to exterior use only.

One major advantage of mineral wool insulation lies in the structure of the fibers, which are less brittle than typical fiberglass, allowing it to be compressed into products that are more dense, some that are even classified as rigid board. Mineral wool is also unaffected by water and resistant to the absorption of water, making it a good below-grade insulation. It can even act as a drainage board to help keep hydrostatic pressure from building against a foundation wall and assist in shedding water to a subterranean drainage system.

Mineral wool is highly fire resistant, even fireproof in many cases. It is the insulation of choice around wood stoves, flue ducts and other areas requiring re resistance. Lastly, it is resistant to pests. Like polystyrene, it is not a food source for insects or vermin, but insects (ants and termites) love to nest in EPS or XPS if given the chance. Not so with mineral fiber insulation. This also allows one to avoid the toxic pesticides that are sometimes added to these products.

Mineral fiber insulation comes in many densities, configurations, shapes and applications. It is now even able to be used under slabs in some circumstances.

Spray Polyurethane Foam – SPF R-4-7/inch

TYPICALLY, A SPRAY FOAM INSTALLER will don a hazmat grade suit with a respirator, properly ventilate the subject space and commence spraying insulation onto the appropriate surfaces. The spray nozzle is connected to two separated chemicals that converge in the nozzle, where they mix and their chemical reaction begins before being shot onto the subject surface, creating a polyurethane (or polyurethane-like) foam that rapidly expands in place.

If I’d written this article a few years ago, this would be a short section. I would basically say, “Don’t use this toxic stuff,” and that would be that. But the market has been drastically changing and not all spray foams are the same. If you’re thinking about having spray foam installed somewhere, you’ll want to know the good, the bad and the ugly of it all. Let’s start by talking about the two major kinds of spray foam, open cell and closed cell, and the advantages of each.

CLOSED CELL - R7/INCH

As the name implies, the individual air bubbles within the foam are all closed, and the exterior lm that forms on it is closed to air and moisture transmission. Because it acts as both an air barrier and a class one vapor barrier, some builders believe that closed cell spray foam solves all their problems regarding air sealing and vapor control within the wall or roof assembly. To a builder, it takes all the uncertainty and all the thinking out of the equation, which is very appealing — and also untrue. (More on this when we talk about disadvantages.)

If installed properly, closed cell spray foam creates an easy-to-install, high-quality, tight, inert, moisture-resistant, high- performing insulation layer.

OPEN CELL –– R-4/INCH

In 1986 Icynene introduced a water-based spray foam that used C02 as its blowing agent. At the time, closed cell foams were using HCFCs, powerful, ozone-depleting gasses, as their blowing agents. Icynene’s innovation made for a spray foam that was less toxic to install and much more planet-friendly; however, its performance drops to the point that you would need almost twice as much open cell SPF as you would closed cell to do the same amount of insulating. Open cell is still an air barrier, but because of the open cells, water vapor can move through it, so vapor control within the building assembly will need to be managed in another way.

There are numerous brands and types of SPF on the market that give you all the installation advantages of closed cell with the bonus of being much less toxic to installers and the planet.

Toxicity

Watching installers suit up with their respirators and equipment and disappear into a building where no one else is allowed during installation leads one to ask, “What are we doing? What are we putting in our homes?”

If you generically requested closed cell spray foam from your contractor, you would probably get a combination of polyurethane and MDI-related chemicals blown in place by complex HFCs. On their own, these chemicals are quite toxic. The combination mostly cures within one hour, but it can take anywhere from a day to a week to fully cure. Until it does, the SPF outgasses VOCs (volatile organic compounds). If for some reason the mix or curing conditions aren’t right, or too much was applied all at once, that cure time could take much longer or might never fully cure (though this is rare). There have been many instances where a chemical, “dead sh” odor lingers long after the home is complete, resulting in many insurance claims.

“Blue haze” is a condition that sometimes develops after an installation of spray foam where one’s vision appears blurred and blueish. Perhaps one’s mask wasn’t on securely or was removed too early, or maybe the construction crew entered the building too soon after an installation. Whatever the cause, the full effects of too much exposure to these chemicals is not fully known or publicly accessible. This would be enough for me to scrub spray foam from my speci cations completely if the industry weren’t continually moving, innovating and progressing.

Many water-based, soy-based, water-blown, open cell SPFs have greatly reduced their toxins and their blowing agents to the point where I’m quite comfortable specifying the RIGHT spray foam for those tricky spots. But, I’ll also be upset if the contractor switches to a different product, thinking they are doing me a favor by installing a higher performing product, a cheaper product, or one that is easier to acquire so they can stay on schedule, without consulting me.

In fact, our office is presently working on a project for a client who suffers from severe MCS (multiple chemical sensitivity). One of the very few insulations she is comfortable around is Icynene ProSeal Eco, which has an R-value of 4.9 and thankfully a GWP of 1.

GLOBAL WARMING POTENTIAL

When open cell was invented, the ozone layer was the subject of concern; now, global warming is of far greater importance. For this reason, many closed cell foams get a failing grade in sustainability; this is where the difference between the brands really comes to light. When first introduced, closed cell spray foam used blowing agents that had a GWP of over 5000, meaning they were over 5000 times more powerful than C02 as a greenhouse gas. The newest generation of HFC-based blowing agents are still over 700.

Thankfully, most open cell SPF products (and some closed cell) now use C02 (and water) as a blowing agent (GWP=1) while some others use methane (GWP=25).

As an air sealer, it’s good, but not great.

There is a common misconception, especially among builders, that using spray foam on a project means they have just air sealed their building. It’s easy to understand this assumption. Spray foam expands into every nook and crevice, and it IS an adhesive that should stick to anything to which it is applied. However, in some cases the foam expands to ll the cavity, but then shrinks a tiny bit as it cures. Usually it’s able to adhere to the substrate and easily resist the shrink, sometimes not. In most cases it sticks to itself more than it sticks to wood or other products so, over time, as the building moves and the materials contract and expand under various environmental conditions, hairline gaps appear.

It is true that a fair level of air sealing can be done with spray foam, but I have heard plenty of testimony from fellow designers who thought they would easily meet passive house levels of air infiltration with spray foam, only to realize additional steps were required.

Wood fiber insulation board R-5/incH

Photo Courtesy of Go Lab

IF ONE WANTED TO CREATE A LOW CARBON, foam- free building, there’s one commercially available product that stands out as a good replacement for rigid foam board. Wood insulation fiber board is comprised of fluffed wood fibers pressed together with a paraffin and polyurethane-based resin. The product comes in an incredible array of densities and thicknesses. Some boards are flexible enough to be considered batt insulation. The resin makes wood fiber insulation moisture-resistant so it can be used in almost all the same locations as foam boards (just not below grade, yet). The formula of the product also makes it a vapor-open insulation that won’t trap moisture in inappropriate locations. Being made primarily of sustainably harvested or salvaged wood pulp gives this particular insulation a negative GWP (which is a good thing). This family of insulation products is incredibly appealing to the green architects and builders who’ve been wanting to kick the foam boards to the curb for decades.

So why don’t we see more of this material being installed? Price.

At the moment the two major companies providing wood fiber insulation products are Steico of the UK and Gutex of Germany. These products have been used affordably in Europe for decades, but only recently here in the U.S., where small supply and travel costs keep the premium high.

But there’s a local hope waiting in the wings: GO Lab, a Maine- based company, is about to begin production of three different kinds of wood fiber insulation. Their new manufacturing facility in Madison (the former Madison Paper Mill) is planning to make wood fiber insulation products available in 2021 and 2022. The loose ll product will have an R-value of 3.8, the batt product is expected to be slightly more insulative than dense packed cellulose at R-4/inch, and the board product will be equal to EPS at R-5/inch and will be available in thicknesses up to 10”.

As a Maine architect, I can’t wait to start using this product in our projects. I can’t think of a better way to end this article than by highlighting a local option from a company restoring an old mill and creating a new economy sector dedicated to improving the environmental performance of our buildings. In the end, it’s what our insulation is meant to do — reduce our consumption and our pollution and keep us warm, safe and comfortable for this and future generations. G&HM

This article appeared in the Fall 2020 edition of Green & Healthy Maine HOMES. Subscribe today!