As Maine GOes…

Maine-based GO Lab first in u.S. to create wood fiber insulation

By Lee Burnett

Josh Henry was unimpressed with his first visit to a modern energy-efficient home under construction. The one-time University of Maine materials chemist had been drawn to work in the performance building industry because of its environmental ethic. But he cringed at the sight of rigid foam insulation panels wrapping the building.

“So, it’s just a giant beer cooler?” he recalled saying. Henry’s wake-up moment helped propel GO Logic, the pioneering Belfast design and construction firm where he consulted, to move away from petroleum-based foam insulation. The ensuing search eventually led Henry and partner Matt O’Malia to found a brand-new company, GO Lab. Last year, GO Lab acquired a cavernous former paper mill in Madison and is planning to invest $70 million to become the first US manufacturer of wood fiber insulation. Production is expected to start later this year.

“Building products is a $10 billion industry in the US and it’s undergoing a sea change,” Henry told an audience of several hundred people at the Maine Woodland Owners Forestry Forum earlier this year. The drivers, he said, are the growing urgency of combating climate change and ever tighter building and energy codes. “We need to change how we heat and cool buildings. We also need to change how we build buildings. This is something we can do. This is not that hard.”

Although wood fiber insulation has just a toe-hold in Europe, GO Lab expects a much bigger footprint in the US.

“We anticipate building ten to fourteen mills [nationwide] in the next ten to twenty years,” Henry said.

Bold statements from the forest products industry tend to be taken in stride by mill towns accustomed to the ups and downs of the paper industry. By contrast, Henry’s message seems to resonate across sectors, whether he is speaking to landowners, forest certification advocates or performance builders. GO Lab even got a spontaneous shout-out at a Passivhaus Maine event in January.

“This [GO Lab] is a fabulous opportunity to also align our economic, political and social priorities across some common good,” speaker Jacob Racusin, a performance builder from Vermont and evangelist for natural building materials, told an appreciative audience of about 60 performance builders in Falmouth. Climate-smart investments in rural communities like Madison are essential to breaking the political impasse over climate action, he said. “One thing that is not politically divisive is economic development,” said Racusin.

Emerald Builders of Bowdoinham, installing wood-fiberboard insulation currently imported from Germany. PHOTO COURTESY OF EMERALD BUILDERS

HERO MATERIAL

Standard insulation – such as fiberglass or various foams – has long been the most basic of building materials. That’s certainly not the case with wood fiber insulation, whose performance characteristics and miniscule carbon footprint have elevated it into the status of “hero material” by builders like Racusin.

Insulation is a complex consideration in the construction of modern buildings. Insulation improves the energy efficiency of heating and cooling, but it also increases the risk of trapping moisture in walls, where mold and rot can grow unseen. In Maine, moisture migration is seasonally dynamic. During the winter, warm, moist inside air tends to migrate and condense on cold outer walls, while in the summer, muggy outside air tends to migrate and condense on cool inside walls. (The summer air movement is lower because the indoor-outdoor temperature differential is slighter.) The moisture problem can be addressed with vapor barriers, to keep it out of walls, and mechanical ventilation systems, neither of which is foolproof.

Chart adapted from an image created by foursevenfive.com. The embodied carbon footprint of Maine-produced insulation should be even lower than the German-produced products because of shorter transportation distances. Embodied carbon is the CO2 emitted during the manufacture, transport and construction of building materials.

“As the building codes get tighter and stricter, it’s forcing us to get a lot smarter about how we construct wall systems, so we don’t create more issues,” explains Emily Mottram, a high-performance building architect in Cumberland. The remedy growing in popularity is “vapor-open” materials that retard air movement but still allow moisture to dry out on both sides. They operate in a similar way to a Gore-Tex rain jacket. Vapor-open materials are especially useful in meeting requirements for “continuous insulation” in residential and commercial construction. Continuous insulation is essentially a blanket around the building to combat “thermal bridging,” or heat loss, through wall studs and other structural components. “Vapor-open” materials, such as wood fiber insulation, “have the flexibility to meet the codes without creating new issues,” explains Mottram.

Wood-fiber insulation’s miniscule carbon footprint comes from the low-intensity manufacturing process (powered by adjacent hydro-electric dam) and the wood chips’ storage of carbon extracted from the atmosphere by trees grown under sustainable forest management. GO Lab has announced it will buy only chips certified as sustainably grown by the Forest Stewardship Council (FSC), the most rigorous of three forest management auditing organizations.

SUSTAINABLE FORESTRY

At full production, GO Lab expects to buy 230,000 tons of spruce and fir wood chips. Although wood chips are a low-value product, they are key to the entire woods economy as a reward for thinning and improving stands to grow more valuable saw logs. The 100 tractor trailer loads a year rolling into Madison will be a welcome boost to loggers, truckers and landowners who lost markets for millions of tons of chips as a result of paper industry downsizing.

The visibility of an FSC-labeled performance building product in retail lumber yards could be a boon to sustainable forestry in Maine, says one forest certification advocate. Maine is a leader in acres of woodlands under certified management, although you’d never know it by visiting a building supply outlet. Wood is a commodity. Once cut, it disappears into a long supply chain and is eventually sold as generic lumber, paper or plywood. About 15 years ago, Maine pushed forest certification as a way to brand sustainably-grown wood and fetch a higher price. Today, more than half the forest acreage in Maine is managed under a forest certification program. But the wood sells for the same price as other wood and hence has low visibility.

GO Lab’s climate-friendly products could raise the visibility of sustainable forestry, said Alex Ingraham, president of Pingree Associates, one of the landowners who hopes to supply FSC wood to GO Lab. “Having a direct connection [between product and source] may well help,” he said, noting that GO Lab “aligns very nicely with our overall mission.” Pingree Associates and its affiliate, Seven Islands Land Company, has one of the longest track records for careful forest management in Maine, dating to the early 19th century; the company was one of the first landowners in the country to become FSC certified 25 years ago. The alignment of climate-friendly products, sustainable forestry and Maine “could be very, very powerful,” he said.

RURAL REVITALIZATION

In Madison, excitement is building over the prospect of big machines humming again. Currently the machines are in Bremen, Germany awaiting shipment; once assembled, they will cover an area equal to two football fields. GO Lab has hired key operations personnel from the former UPM paper mill whose deep institutional knowledge and facilities expertise have already saved the company millions of dollars, said Henry. “It’s been fantastic,” he said in an interview. “They’re not looking for work, they’re in their 50s and 60s. But they have a lot of pride in the building and for the community. They’re doing this because they want to know, who’s going to be the next generation?”

The installation of wood-fiber insulation is similar to other rigid panel insulation, as Emerald Builders demonstrates in this photo. PHOTO COURTESY OF EMERALD BUILDERS.

Henry describes himself as “pretty passionate” about Maine’s wood culture — the multi-generational family ownerships, skilled workforce, the automation of processes and the deep woods lore. “If you’re a young engineer and want to have a big impact on the forefront of the economy, the wood products industry is a great place to be working,” he said. He wonders why Brooklyn hipsters aren’t wearing Robbins Lumber hats. “Authentic is something that has value. People don’t know where to find it. We have it in abundance in Maine and we need to talk more about it.”

GO Lab expects to eventually hire 120 employees, half of whom will have technical backgrounds. Even the semiautomated production jobs will require at least an associate’s degree. If you want to know who will be filling those jobs Henry suggests a visit to GO Logic offices in Belfast, a community where he says the average age is 50 or 60. “In our office, the average age is 30,” he said. “They come from all over. They want to be in Maine … we have the power to attract young people who want to work and have a positive impact.”

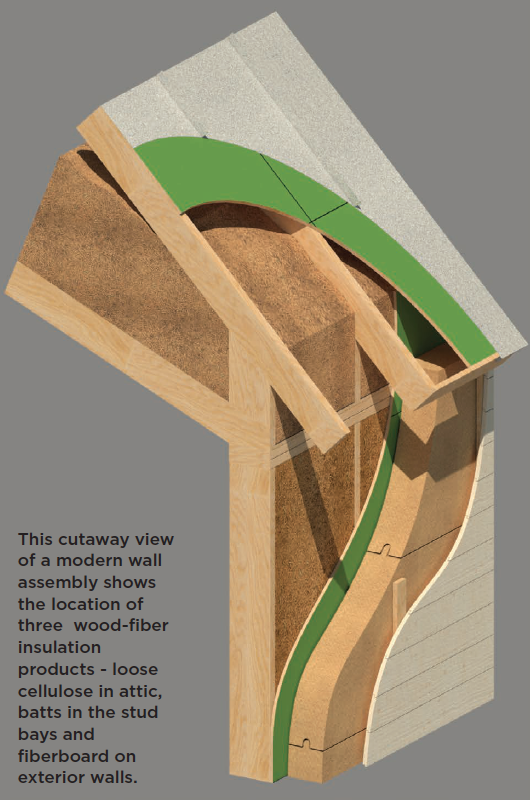

ILLUSTRATION COURTESY OF GO LAB

TOUCH AND GO FINANCING

All the goodwill GO Lab is generating has not translated into money from banks.

On paper, GO Lab does not appear to be a particularly risky enterprise. To start with, wood-fiber insulation is not all that innovative. They’ve been manufacturing it in Europe for 25 years in a process similar to other fiberboard products such as medium density fiberboard and hardboard. GO Lab acquired plant and equipment at fire-sale prices. The former UPM Mill in Madison, which saw a $300 million investment in 1981, was acquired for $1.9 million. Similarly, a $30 million fiber making machine was acquired for $2 million. “We caught a few breaks,” said Henry. In addition, the wood-fiber insulation market, which corresponds closely with the residential wood frame construction market, is potentially much bigger in the US than Europe. In Europe, only 20 percent of homes are wood, and the market has grown to $500 million-plus, while in the US nearly all homes are built of wood and GO Lab would seem to have the US market all to itself, at least at the start, because of the high cost of shipping a light, bulky material across the ocean. “Five thousand dollars of material costs five thousand dollars to ship,” Henry points out.

Despite all these advantages, start-up financing has not been easy to secure, according to Henry, who ticked off all the new-market uncertainties that would give a lender pause. “It’s easier to finance a three hundred-million-dollar paper mill than a wood-fiber insulation or biofuels mill,” he said.

HOW WILL BUILDERS RESPOND?

GO Lab’s vision is to disrupt the insulation market with three products — loose fill, batts and fiber-board panels — each of which is virtually interchangeable with existing products. Henry acknowledges that success depends on reaching beyond performance builders with “cost-competitive pricing.” “We want to talk to the average builders, not just the building scientists,” said Henry.

Local builders and suppliers familiar with the product say switching to wood insulation won’t require much of a learning curve. It will all depend on pricing. Emerald Builders in Bowdoinham already use Gutex wood-fiber insulation board imported from Europe, a similar product. “Anyone working with an exterior insulation, this is going to be easy to plug into,” said Reggie Lebel, owner of Emerald Builders. CD Armstrong, owner of Deering Lumber, thinks the average builder is content with current options, but will switch as energy codes tighten. “I think the average builder will eventually adopt it, but it will take time,” he said.

Mark Hopkins, chief operating officer for Hancock Lumber says, “It will take some time to get used to, and education will help.” As long as pricing is competitive “it could displace everything on the market, batt-style, board. I don’t think there’s a limit.”

If GO Lab succeeds in disrupting the insulation market, the result could be a durable alignment of urban sustainability, rural revitalization and sustainable forestry.

Now, that might get Brooklyn hipsters rocking GO Lab gear.

Lee Burnett is project director of Local Wood WORKS. He makes it easier to source sustainably-produced Maine wood products by organizing tours and presentations and by maintaining the online Maine Wood Guide and Product Master Spec for Local Wood at www.localwoodworks.org.